EC-TRINCAS

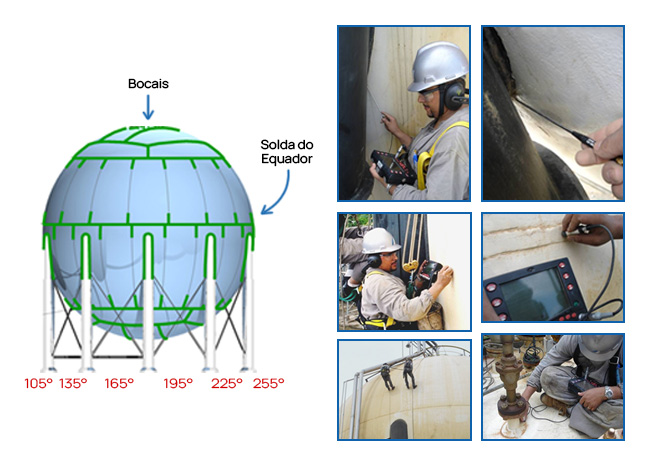

Exame de chapas, juntas e soldas (zonas termicamente afetadas pelo calor (ZTAs) e suas adjacências) de praticamente todos os materiais metálicos utilizados na indústria, tais como aços carbono, aços baixa-liga, aços inoxidáveis austeníticos, alumínio, cobre e titânio (e suas ligas) em praticamente todos os tipos de equipamentos metálicos, tais como vasos de pressão, caldeiras, tubulação, aeronaves, pontes, plataformas de petróleo, submarinos e grandes estrutura metálicas.

A técnica é versátil e os equipamentos utilizados para exame no campo são leves, resistentes e práticos, o que permite sua aplicação em locais de difícil acesso, desde pequenas frestas e furos até inspeções submarinas. Existe uma grande variedade de sondas e cabos com até 100 metros de comprimento. O exame pode ser executado sobre camadas de tinta e em superfícies sem preparação rigorosa, além de dispensar utilidades tais como energia elétrica, ar comprimido e água no local do exame. O método de eddy-current é aprovado pela comunidade européia e qualificado pela PNC e ASNT. O exame de soldas é executado conforme a norma EN BS 1711:2000.

A técnica é versátil e os equipamentos utilizados para exame no campo são leves, resistentes e práticos, o que permite sua aplicação em locais de difícil acesso, desde pequenas frestas e furos até inspeções submarinas. Existe uma grande variedade de sondas e cabos com até 100 metros de comprimento. O exame pode ser executado sobre camadas de tinta e em superfícies sem preparação rigorosa, além de dispensar utilidades tais como energia elétrica, ar comprimido e água no local do exame. O método de eddy-current é aprovado pela comunidade européia e qualificado pela PNC e ASNT. O exame de soldas é executado conforme a norma EN BS 1711:2000.

PRINCIPAIS vANTAGENS

– Preparação de superfície menos exigente;

– Não requer remoção de pintura;

– Não requer consumíveis;

– Não requer utilidades (água, energia ou ar comprimido);

– Processo rápido, limpo e eficaz;

– Mais rápido que partículas magnéticas e liquido penetrante;

– Permite registro da calibração e da inspeção, e consequentemente do acompanhamento da evolução das descontinuidades;

– Vantagens sob os ensaios de ACFM / Liquido Penetrante e Partículas Magnéticas (ver documentos adicionais “ACFM x EC” e “EC x PM_LP”.

– Não requer remoção de pintura;

– Não requer consumíveis;

– Não requer utilidades (água, energia ou ar comprimido);

– Processo rápido, limpo e eficaz;

– Mais rápido que partículas magnéticas e liquido penetrante;

– Permite registro da calibração e da inspeção, e consequentemente do acompanhamento da evolução das descontinuidades;

– Vantagens sob os ensaios de ACFM / Liquido Penetrante e Partículas Magnéticas (ver documentos adicionais “ACFM x EC” e “EC x PM_LP”.