vasos

Exame global por emissão acústica de vasos de pressão em operação e durante testes de pressão, tipicamente aplicado como parte de planos de inspeção. Estudamos e desenvolvemos procedimentos para aplicações específicas.

Temos experiência de 25 anos e “know-how” baseado em resultados comprovados em aplicações efetivas de emissão acústica em diversas partes do mundo. Nosso diferencial, além da utilização de métodos consagrados pelo uso, utilização de aparelhos e softwares de ultima geração é nossa especialização em “Inspeção de Equipamentos”.

Nossos métodos para monitoramento contínuo, principalmente de equipamentos danificados, estão baseados em uma análise profunda e especializada do comportamento mecânico do equipamento, mecanismos de deterioração, cinética de nucleação e propagação dos danos associados e estudo das variáveis de processo.

O acesso aos dados de emissão acústica é feito online, por via da internet. Para análise dos dados gerados e conclusões, são considerados os dados coletados periodicamente por nossos técnicos nos “sites” para coleta das informações de processo, verificação dos aparelhos e calibração de sensores.

O exame por emissão acústica é dividido nas seguintes fases importantes:

PRIMEIRA FASE

planejamento por engenharia especializada

– Levantamento de dados de processo, projeto, histórico de operação, inspeção e manutenção;

– Elaboração do procedimento de teste, com base na avaliação e interpretação dos dados levantados, dos objetivos do teste e das normas aplicáveis, por engenharia especializada².

SEGUNDA FASE

EXECUÇÃO DO TESTE

Os testes são executados com equipamentos e softwares¹ tecnologicamente atualizados e de ultima geração.

TERCEIRA FASE

ANÁLISE E INTERPRETAÇÃO

Os resultados dos testes são interpretados e avaliados segundo os objetivos definidos no procedimento, por engenharia especializada². Os resultados indicam claramente os locais das descontinuidades e os exames não destrutivos mais adequados para sua identificação e dimensionamento (incluem técnicas convencionais e não-convencionais) e sua “significância”. Os dados são interpretados em conjunto e por canal, mediante a aplicação de técnicas específicas para identificação do tipo de fonte e sua significância.

QUARTA FASE

CONCLUSÕES E RECOMENDAÇÕES

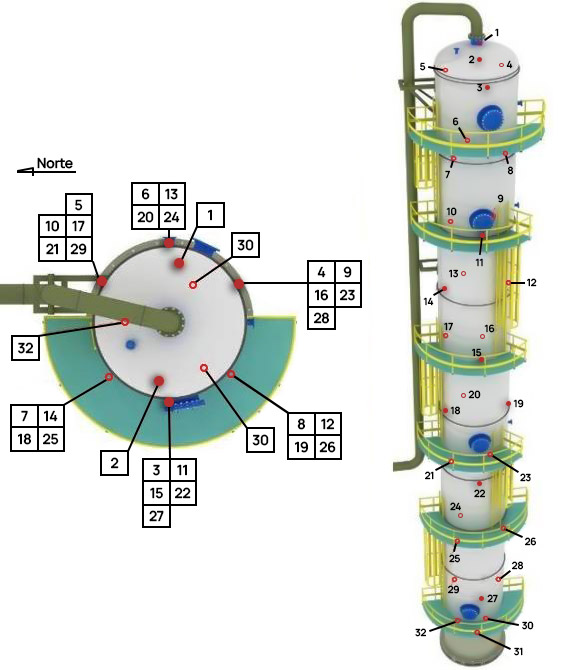

As recomendações são emitidas na forma de “desenhos planificados em escala”, contendo a localização das regiões a serem inspecionadas e as técnicas de ensaios não-destrutivos recomendadas para cada uma delas. Nossa equipe técnica se dispõe a auxiliar na identificação dos locais a serem inspecionados por outras técnicas nos equipamentos durante as inspeções, quando aplicável.

QUINTA FASE

emissão dos

relatórios

Os relatórios incluem todas as informações geradas durante os ensaios, as análises e conclusões. O posicionamento dos sensores é feito em desenhos 3D, para facilitar sua localização e correlação com características físicas do equipamento. As regiões ativas e indicadas para inspeção são mapeadas em desenhos planificados em escala.

1 – EQUIPAMENTOS E SOFTWARES: Utilizamos equipamentos fabricados pela empresa Vallen System de ultima geração, são os únicos equipamentos certificados pela TUV. A analise dos dados de EA é executada pela ultima revisão dos softwares especificos.

2 – ENGENHARIA ESPECIALIZADA: Equipe composta de engenheiros e técnicos com comprovada experiência (superior a 20 anos) na área de inspeção, deterioração e avaliação de integridade de equipamentos, e emissão acústica. Fazem parte da equipe os engenheiros Cláudio Allevato e Mauro D. Araujo.