EC-CAMPO REMOTO

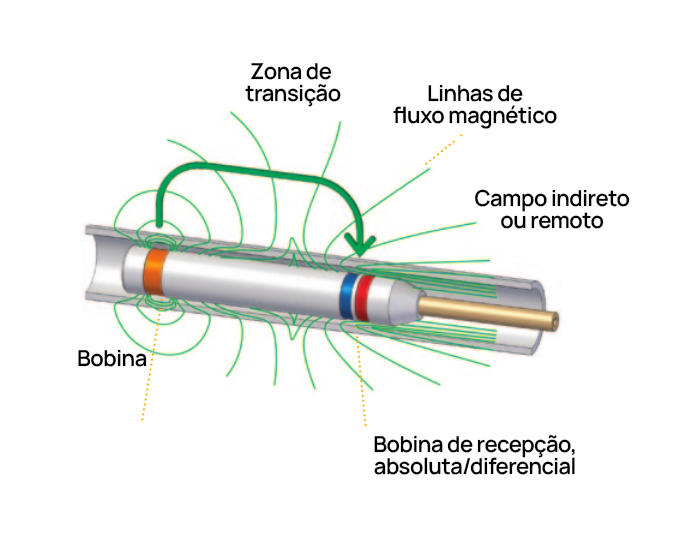

É uma técnica do método eletromagnético, que consiste na “varredura” de todo o comprimento do tubo utilizando-se sondas que emitem um campo magnético que é atenuado pelo “volume de material” existente entre o emissor e o receptor. Uma correlação entre a intensidade do campo magnético “sentido” e a espessura dos tubos, “plano de voltagem” é a base para a detecção e dimensionamento da espessura real dos tubos.

A utilização de duas frequências para eliminar sinais indesejáveis, o recurso de “compensação de frequências”, a utilização de equipamentos e softwares atualizados que permitem a apresentação dos dados em tempo real e a gravação simultânea para analise posterior, são fatores decisivos na precisão dos resultados, assim como na maximização da velocidade de inspeção.

A utilização de duas frequências para eliminar sinais indesejáveis, o recurso de “compensação de frequências”, a utilização de equipamentos e softwares atualizados que permitem a apresentação dos dados em tempo real e a gravação simultânea para analise posterior, são fatores decisivos na precisão dos resultados, assim como na maximização da velocidade de inspeção.

PRINCIPAIS

VANTAGENS

– Permite a inspeção de tubos parcialmente incrustados;

– Baixo fator de enchimento (menor que o eddy-current);

– Sondas flexíveis para inspeção de partes curvas de tubos, tipicamente utilizados em caldeiras;

– Velocidade de ensaio superior ao IRIS.

PRINCIPAIS

desVANTAGENS

– Aplicável somente na Inspeção de materiais magnéticos;

– Não detecta danos sob chicanas e espelhos;

– Possui limitações para detecção de pequenos danos;

– A execução do exame e a interpretação dos resultados exige experiência e habilidade;

– Exige a fabricação de padrões para cada tipo de tubo examinados;

ALGUNS DE NOSSOS DIFERENCIAIS

- Supervisão por equipe de engenharia multidisciplinar com experiência em inspeção e manutenção de equipamentos. Vasto acervo de registros dos diversos tipos de danos que ocorrem em tubos de trocadores de calor e caldeiras.

- Inspeção 100% gravada, os dados podem ser re-avaliados a qualquer momento, ou até mesmo serem comparados em inspeções futuras.

- Procedimento de trabalho com analise imediata dos dados no campo, ou coleta e análise simultânea, este ultimo recurso permite otimizar o tempo de trabalho efetivo em campo.

- Registro dos dados em croqui 3D

- Estatísticas da Inspeção

- Profissional qualificado em Eddy Current conforme SNQC – ISO 9712

- Profissional próprio SNQC Nível III em Eddy Current

- Possibilidade de aplicação de técnicas eletromagnéticas simultâneas (EC, IRIS, RFT, MFL) para complementação e aumento da efetividade da inspeção.